Online Monitoring – Early detection and diagnosis of initiating damages in turbo generators

Frank Ewert Siemens AG Energy Sector Service Division

Introduction

The influence of renewable energy – especially wind energy – is increasing. This trend results in an increased requirement of medium and peak load operation of fossil power for the stabilization of the electrical grid. Especially for large fossil power plants this medium and peak load operation results in an increased thermo-mechanical stress for the core components like the generator due to the increasing number of load cycles.

This typically results in an accelerated aging of the machines and the risk for damages and unexpected failures. As a preventive measure inspections in more frequent intervals offer insight into the condition of the generator, but they cost expensive outage time of the power plant. To minimize loss of revenue, it is helpful to use online condition monitoring and diagnosis systems to receive information about the state of the machine during operation. This will lead to condition based maintenance with extended operating periods in between stand stills.

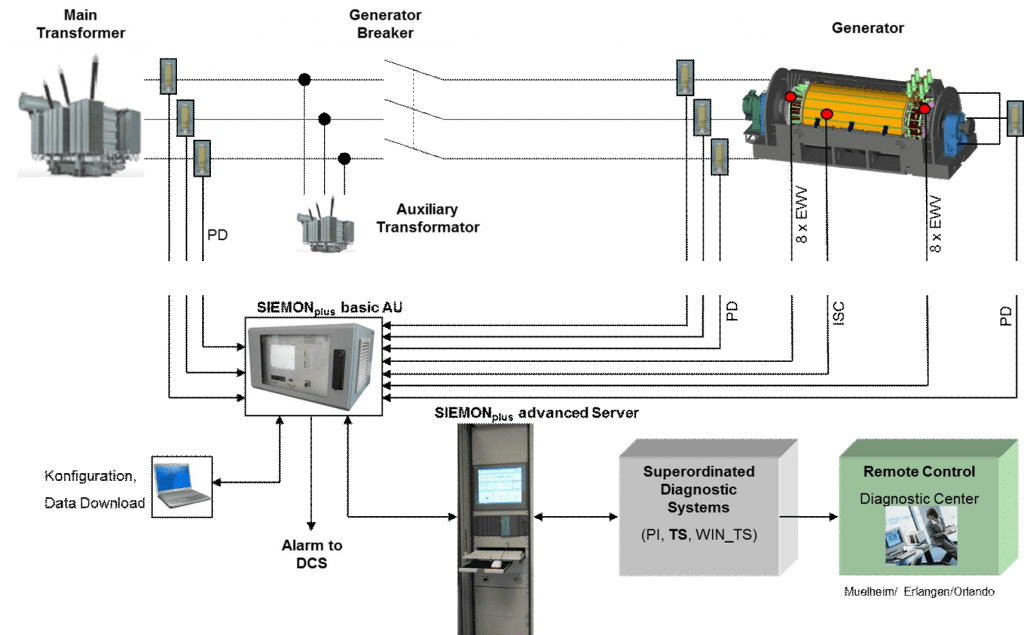

a) Online monitoring of partial discharges enables the user to detect an abnormal condition in the electrical insulation system of the generator.

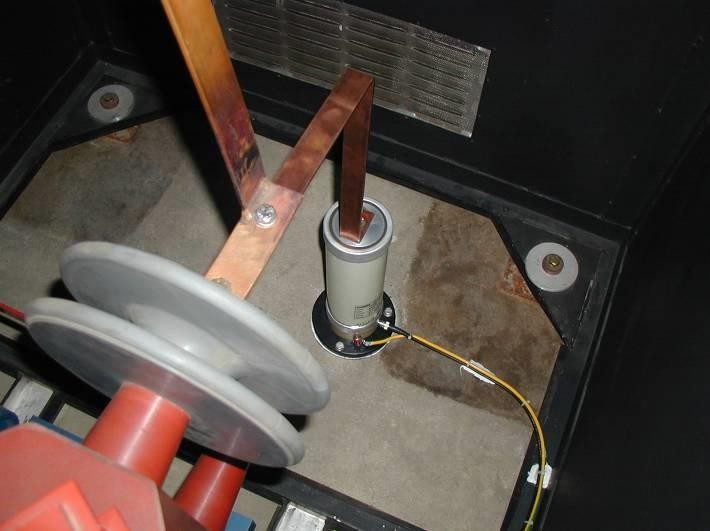

b) Online monitoring of stator end winding vibrations yields information about the actual vibrations during operation, e.g. depending on the specific load point.

c) Online monitoring of the air gap magnetic flux helps to identify interturn short circuits within the rotor windings.

Only the interaction of the above mentioned online monitoring systems in correlation with the operational parameters enables a powerful generator diagnostic.

Keywords: stator, Monitoring, Partial Discharge, Siemens, Generator, PD localization