What can go wrong during stator coil partial discharge measurements according to IEC 60270

William Veerkamp The Dow Chemical Co, 1254-Enclave Parkway, Houston, TX, USA

Saeed Ul Haq, Luis H. A. Teran, Meredith K. W. Stranges GE Power Conversion, 107 Park Street North, On, Canada

ABSTRACT

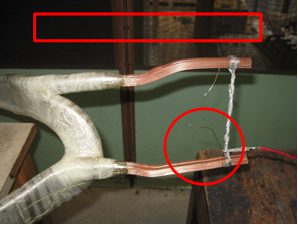

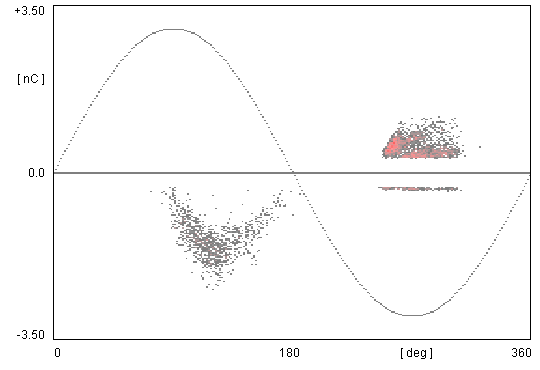

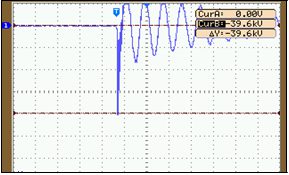

The available literature on partial discharge (PD) analysis suggests that measurements should be performed at higher frequency bandwidth than the conventional IEC 60270 methods, to enhance capability for detection of stator coil defects. In an energized test object, electrical disturbances or noise can strongly influence the observed PD magnitude. Spurious PD could be due to proximate sparking of imperfectly earthed objects, loose connections in the area of the high voltage, electromagnetic radiation, contact noise, broadband noise or loosely applied slot simulating earthing fixtures. Various international standards recommend adjustment of frequency bandwidth to acquire genuine PD signals by enhancing the signal-to-noise ratio. IEEE Std. 1434-2000, suggests an acquisition frequency of 2 MHz with adjustable bandwidth.

Once an appropriate data acquisition bandwidth is established, the recommended approach to determine expectations for PD magnitudes on new factory windings is to compare PD magnitudes with the machine manufacturer’s historical distribution, developed for windings with similar geometry, voltage rating and insulation system construction. This will be more meaningful than attempting to establish an absolute limit based on voltage rating.

Keywords: Partial discharge, frequency bandwidth, noise, stator coil, insulation system.